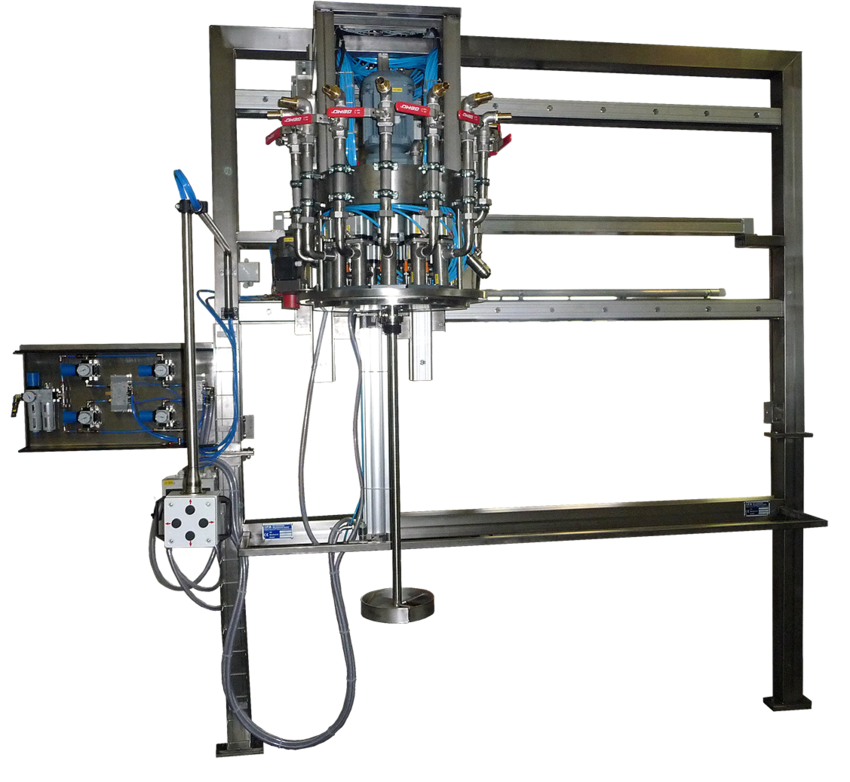

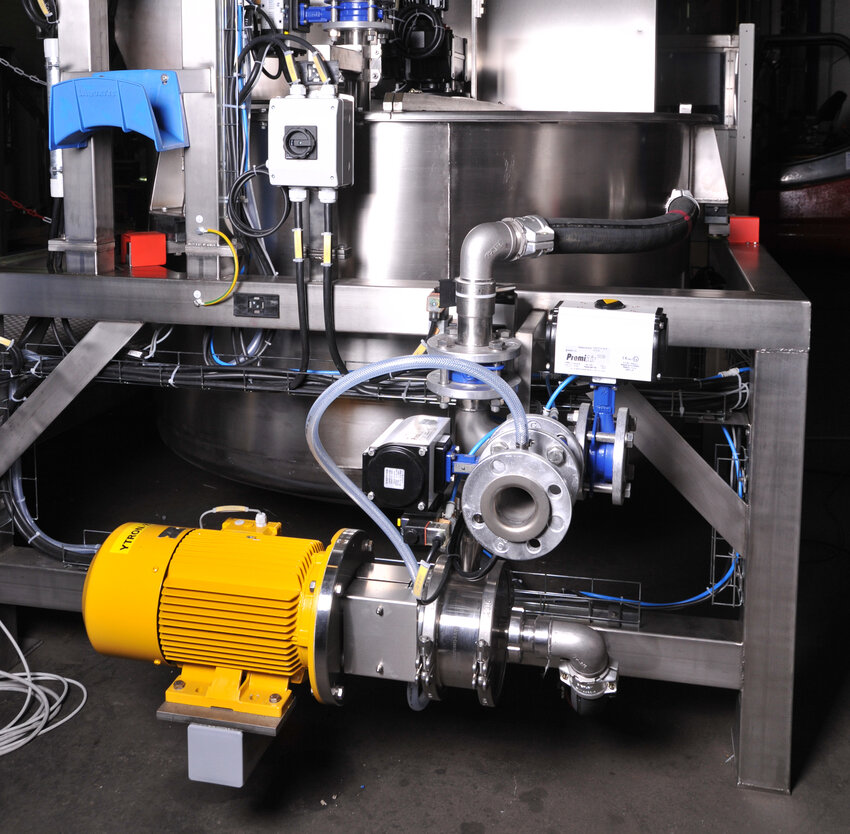

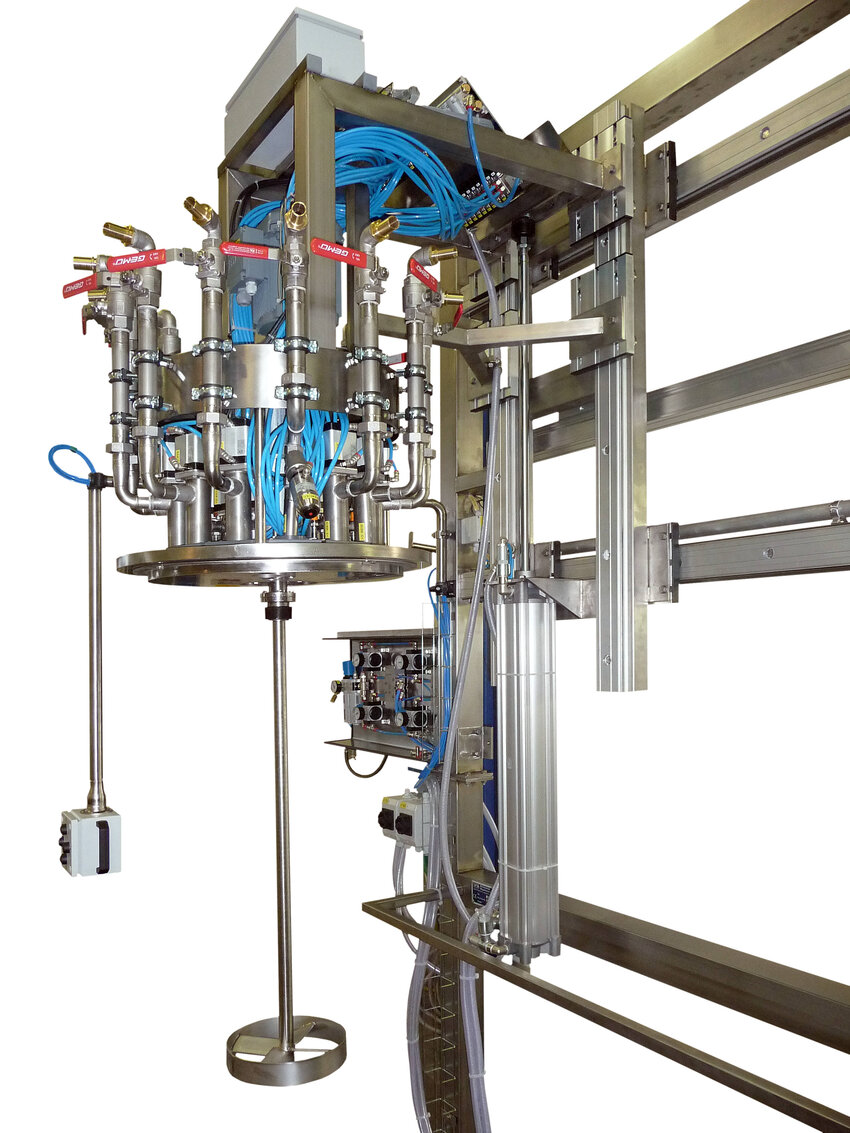

Paint mixing systems

IFA Technology offers customized paint mixing systems for the paint and coatings industry as well as other sectors such as the chemical, food and building materials industries. These systems guarantee the highest quality, efficiency and safety when processing a wide range of materials and are tailored to the specific requirements of the respective production processes. Our expertise provides you with a reliable solution for your color mixing that is both precise and economical.