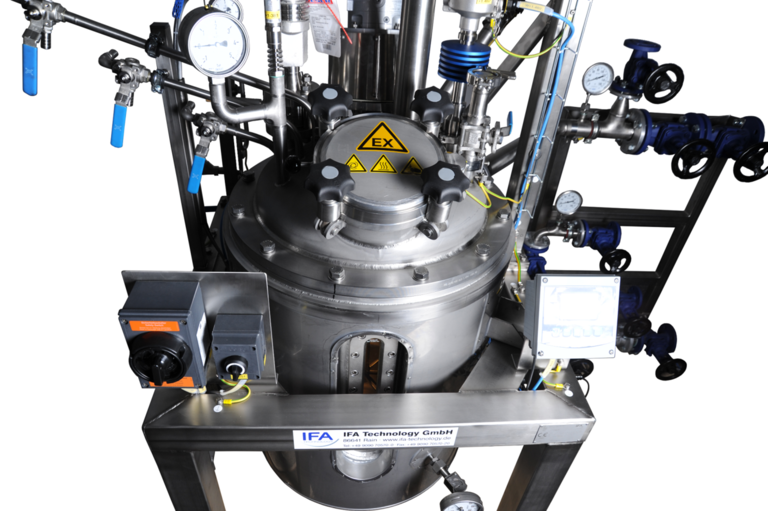

Plant engineering for pharmaceutics

Automatic systems for the pharmaceutical industry that ensure the highest efficiency and precision in the production of active ingredients, tablets, liquids and granules. The innovative solutions meet the strict requirements of pharmaceutical production.