Gravimetric dosing is based on the principle of weight measurement and offers superior accuracy compared to volumetric dosing systems. This is particularly important in critical production processes where even the smallest deviations in dosing can have a significant impact on product quality and production costs.

The exact weight measurement of the materials ensures a constant dosing rate that is independent of density deviations or other physical properties of the materials.

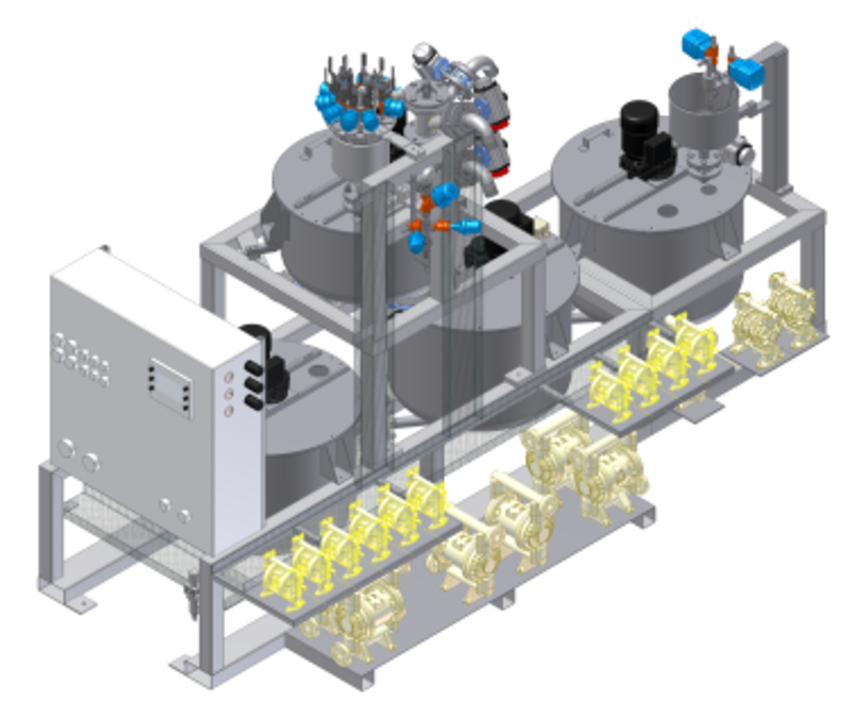

An outstanding feature of IFA dosing systems is their flexibility and versatility. These systems are designed to be suitable for both small and large production volumes. The systems are available in various configurations that can be adapted to specific production requirements.

Functions such as parallel dosing of several substances simultaneously, automatic density adjustment and integrated recipe management offer a high level of efficiency and flexibility, which is reflected in shorter production times and better cost control.