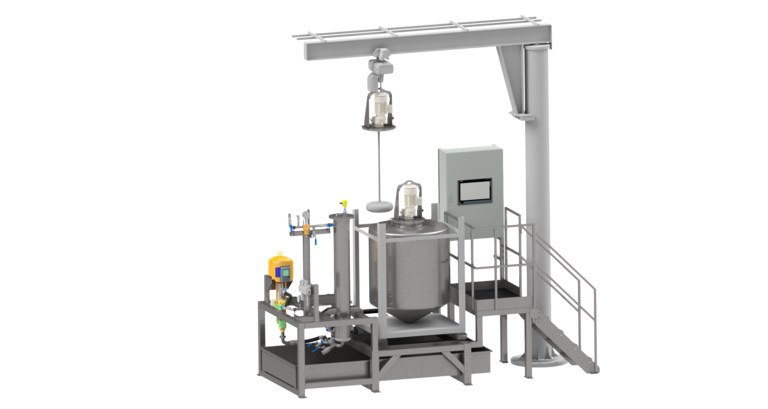

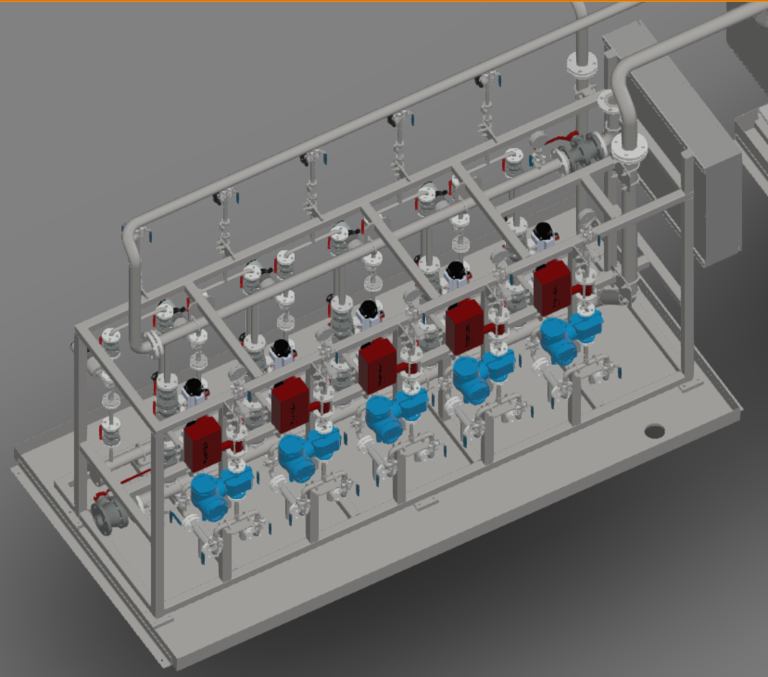

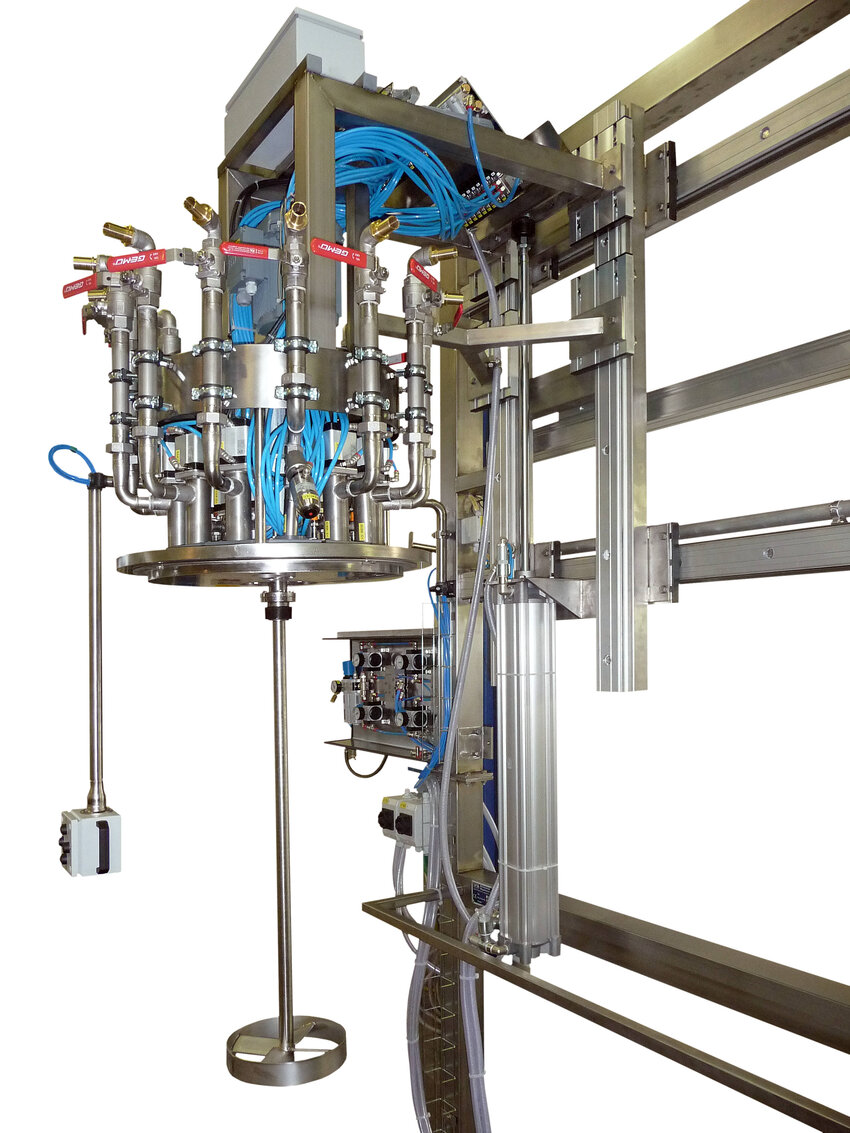

Volumetric dosing systems

Volumetric dosing systems from IFA Technology offer maximum precision and reliability in the quantity-related measurement of liquids and bulk solids in transit. These systems deliver exactly the right amount of material at the right time, ensuring high dosing speed and flexibility. These dosing systems are ideal for numerous industrial applications and reliably meet production requirements.

Our systems use advanced volumetric meters, pulse counters or belt weighers that are individually adapted to the application and material. These precise measuring instruments ensure that the exact amount of material to be dosed is recorded and fed into the production system. This is particularly important for exact recipes and strict quality specifications.