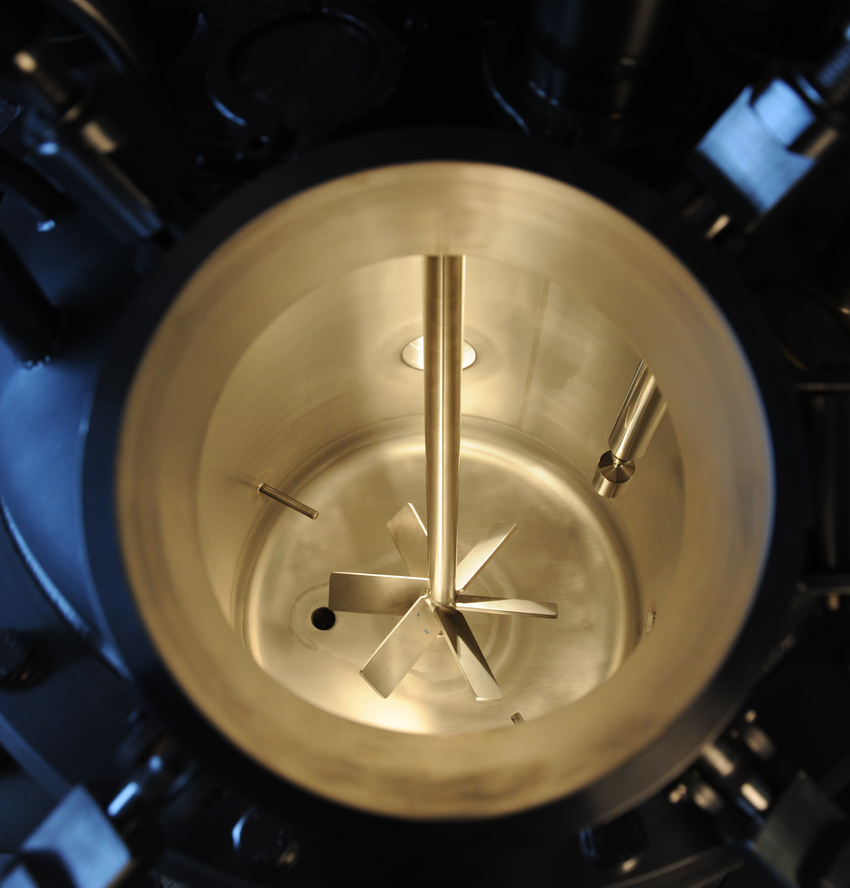

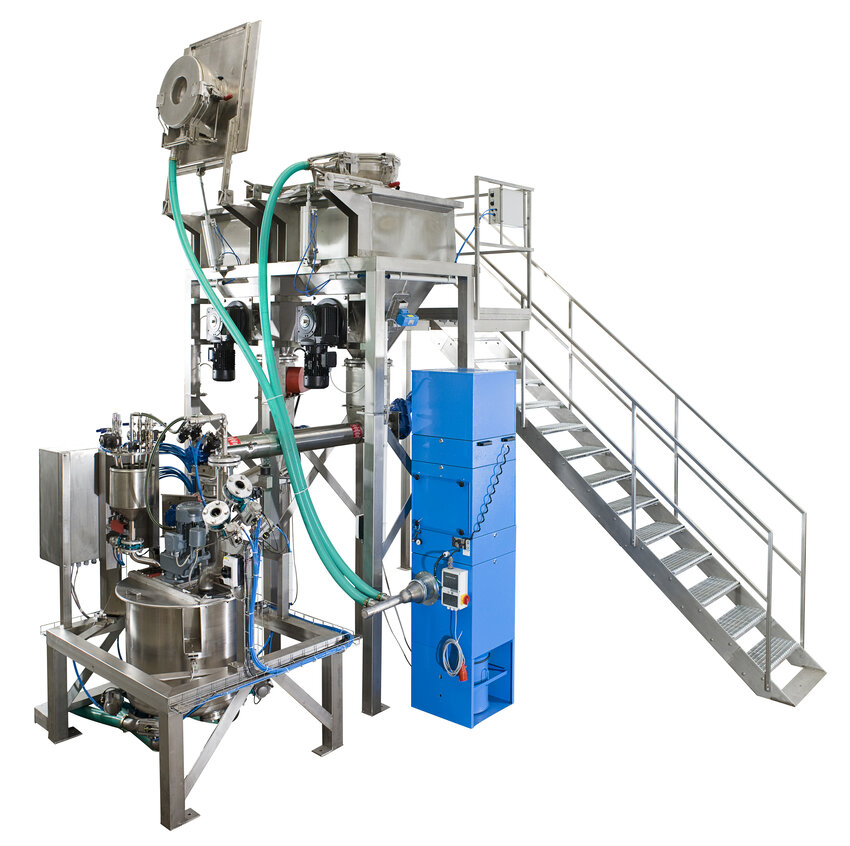

Agitator technology is one of the most frequently used methods in mixing technology, especially in batch processes in which solids are mixed with liquids or liquids are mixed with each other. As a rule, a mechanical agitator is used that promotes the movement of the mixture and ensures even distribution using various stirring devices such as propellers, pitched blades or cups.

The main advantage of agitator technology is its high degree of flexibility: it is suitable for a wide range of materials and aggregate states, from highly viscous liquids to solids and emulsions. This versatility makes it particularly valuable in production processes where a uniform mixture is required. This technique has proved to be extremely effective, particularly in the chemical and pharmaceutical industries, where homogeneity is of central importance.

Technical details:

IFA Technology's agitator technology can be flexibly adapted to meet a range of different requirements.

- Agitator shafts: made of plastic, stainless steel or with special coatings.

- Agitator blades: the number and geometry are individually matched to the specific needs of the application.

- Viscosity: processing from 0 to 150,000 mPas

- Speeds: range from 0 to 3,000 revolutions per minute, as required

This is how we ensure optimal adaptation to your production requirements and achieve constant mixing efficiency.