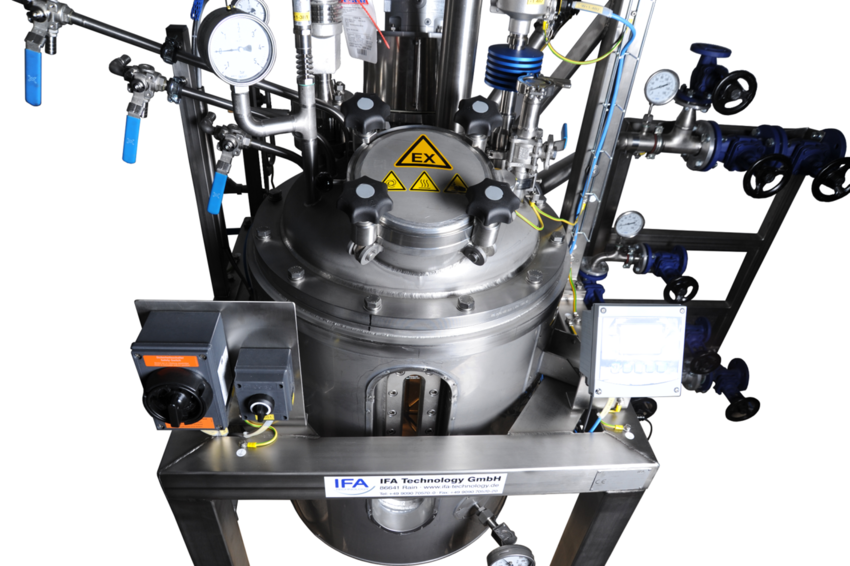

Chemical reactors

Chemical reactors are key elements in the chemical industry. They enable the precise execution of chemical reactions and make a decisive contribution to efficiency and quality in production. IFA Technology offers you high-quality chemical reactors that are optimally tailored to your specific requirements and meet the highest safety standards.