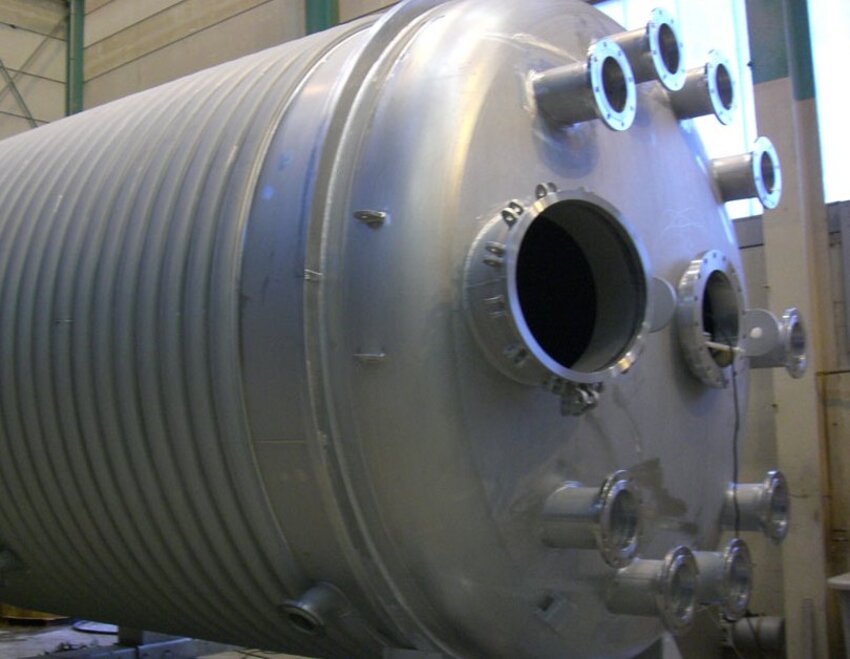

Resin reactors from IFA Technology offer customized solutions for the production of various resins, such as epoxy resins, phenolic resins, polyester resins and various formaldehyde resins (UF/UMF/MF/MUF), as well as base materials for paints and varnishes. These reactors are particularly important for the wood-based materials industry, where they are used for the production of glues and impregnating resins, which play a central role in furniture production, in the construction industry or in the surface treatment of wood products.

IFA Technology's resin reaction systems are flexible and can be adapted to the specific requirements of customers. They enable the production of resins with special properties such as low emissions, high moisture resistance or flame retardancy. In addition, antibacterial properties can be integrated, which is particularly important for applications such as weather resistance and the protection of buildings. These tailor-made solutions offer high versatility and help to maximize the quality and performance of the end products.

Our turnkey solutions offer a holistic service that covers all phases of project implementation - from planning and design to installation and commissioning of the entire production plant. IFA Technology not only supplies the resin reactor, but also all the necessary components to provide a complete turnkey solution. This service also includes technical consulting, the development of customized formulations in cooperation with our technology partners and comprehensive training by our experts to prepare your employees optimally for the operation of the plant.

Request resin reactor