Plant construction for plastics

Precise metering, efficient mixing and optimized processes for the production of compounds, masterbatches, PVC dryblends, pipes, profiles and films – for top product quality and production reliability.

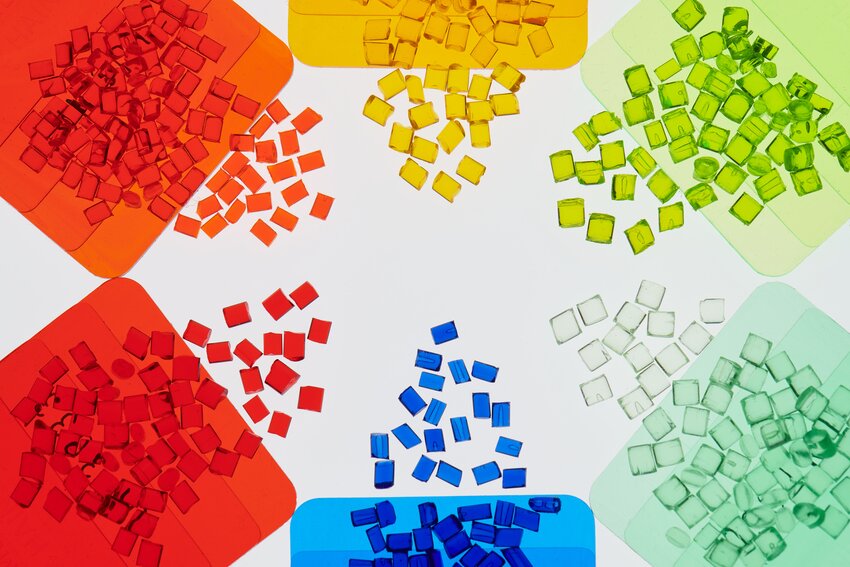

In the plastics industry, precise metering and efficient mixing are crucial to the manufacture of high-quality products such as plastic compounds, masterbatches, PVC dryblends, pipes, profiles, sheets, films and floor coverings.

IFA Technology provides customized solutions for mixing, metering and process optimization that are specifically tailored to the requirements of the plastics industry. Our innovative systems for plastics production enable precise control of process parameters to ensure consistently high product quality and maximum production reliability.

Precise metering and mixing of materials for consistently high quality and optimum efficiency of your products. Flexible adaptation through modular design.

High process reliability and reproducibility to avoid production errors. The systems fulfill all current safety standards, including explosion protection and ATEX guidelines.

Heating and temperature control systems for energy-efficient production, while modular and flexible solutions can be easily adapted to specific production requirements.

The plastics industry faces particular challenges, especially when processing different raw materials and production processes. Precise temperature control for plastics such as polyamides, the processing of highly viscous materials, and precise metering of additives and pigments are crucial to ensure the desired material quality.

The systems, specially designed to meet the requirements of the industry, guarantee the highest precision and a stable process flow in the production of pipes, profiles, films, floor and wall coverings, and wallpaper. With customized solutions, we optimize your production processes and ensure maximum efficiency, reliability, and integrated explosion protection.

Do you have questions about plant solutions for the plastics industry?

Our team of experts is happy to help. Contact us for a customized consultation and further information about our products and services:

What are the main advantages of IFA plant engineering for the plastics industry?

The solutions offer precise metering, high process reliability and flexibility in adapting to your specific production requirements. We ensure consistently high product quality while optimizing the energy efficiency of your production processes.

What safety measures do your systems offer?

All systems meet the highest safety standards, including explosion protection in accordance with the ATEX guidelines. This is how we guarantee the safe handling of materials in plastics production.

How has IFA metering technology developed in the plastics industry?

The first fully automatic metering systems for polyamide production were developed in 1990 in collaboration with a customer. Since then, these systems have been continuously developed and optimized. Today, they enable scrap-free and continuous production that no longer requires operator intervention.