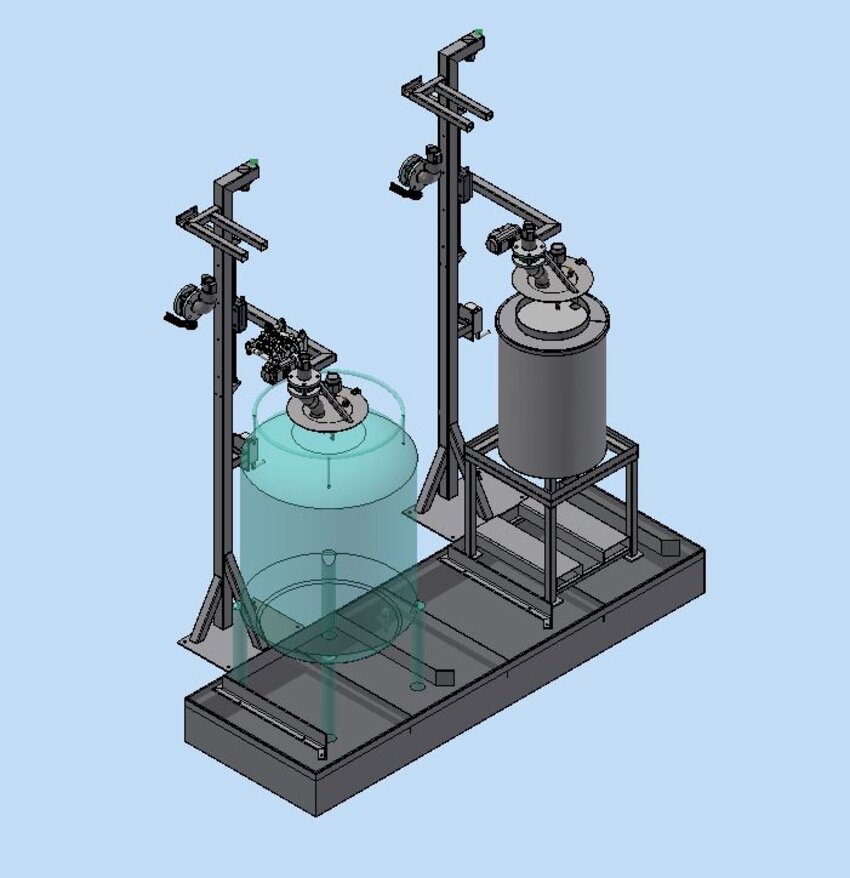

Drum handling for emptying and filling

The handling of liquids and solids in different drum sizes is crucial for modern production processes. IFA Technology supplies advanced drum filling and emptying stations. These are suitable for industries such as chemicals, pharmaceuticals, food and raw materials processing. The systems offer the highest standards of safety, efficiency and user-friendliness and are ideal for hazardous and environmentally harmful substances.

IFA Technology offers customized automated drum handling systems. These optimize production processes and meet the safety requirements of your industry. The stations offer precise handling, high flexibility and a dust-free environment. These features ensure safe and efficient production.