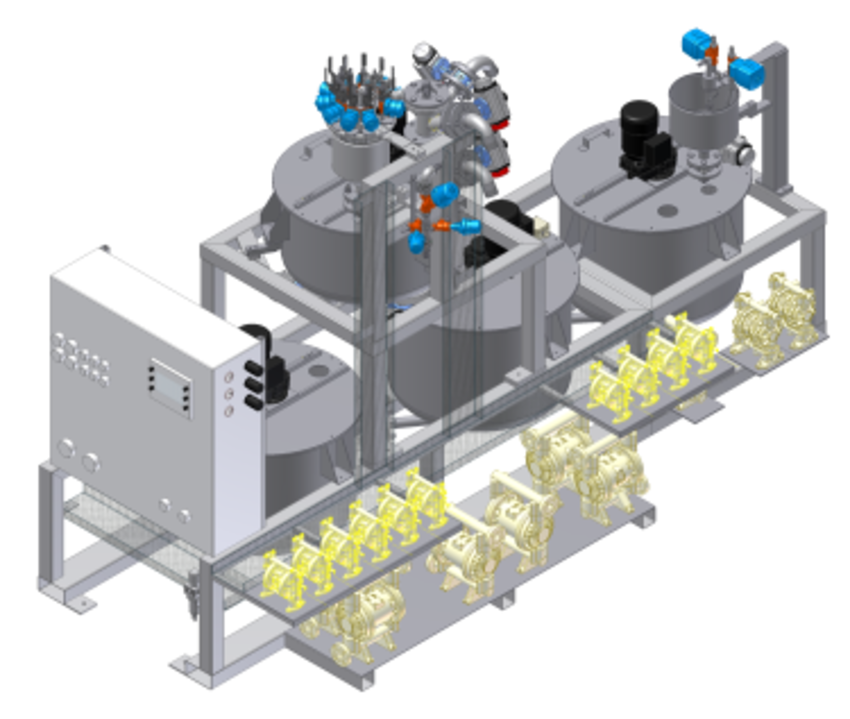

Dosing systems for liquids and solids

Efficient and precise solutions for dosing products, individually adapted to your production requirements.

IFA Technology offers customized solutions for the precise dosing and processing of liquids and solids. Every production has specific requirements that we take into account. We develop gravimetric and volumetric dosing systems, flocculant systems and viscosity control systems. These are tailored precisely to your needs. Whether liquids or bulk solids - our systems optimize your production processes with precise results.

IFA-Benefits

With IFA Technology you receive comprehensive support

We analyze your requirements to find the ideal dosing system for your processes. Our solutions maximize efficiency and accuracy, offer flexibility and ensure your successful production.

We are always available for further information or a personal consultation.

Which dosing system is the right one for my production?

The choice of dosing system is based on factors such as medium, dosing accuracy and production volume. Our experts will advise you on the best solution.

What dimensions do the systems have?

Our Systems cover microdosing from 0.1 g to several tons per hour and are versatile in use.

How long does it take to install a dosing system?

The installation time varies according to size and complexity. As a rule, installation takes several weeks. We develop smaller systems as plug & play.

How much maintenance is required?

Our dosing systems require little maintenance. Our service team carries out regular maintenance and inspections to ensure the reliability and performance of the systems.

Can the dosing system be integrated into existing systems?

Our dosing systems have a modular design and can be easily integrated into existing production lines. We develop customized control systems for seamless integration.